8 Tips for The Selection Technique Of Marking Glass Beads

2025-02-22

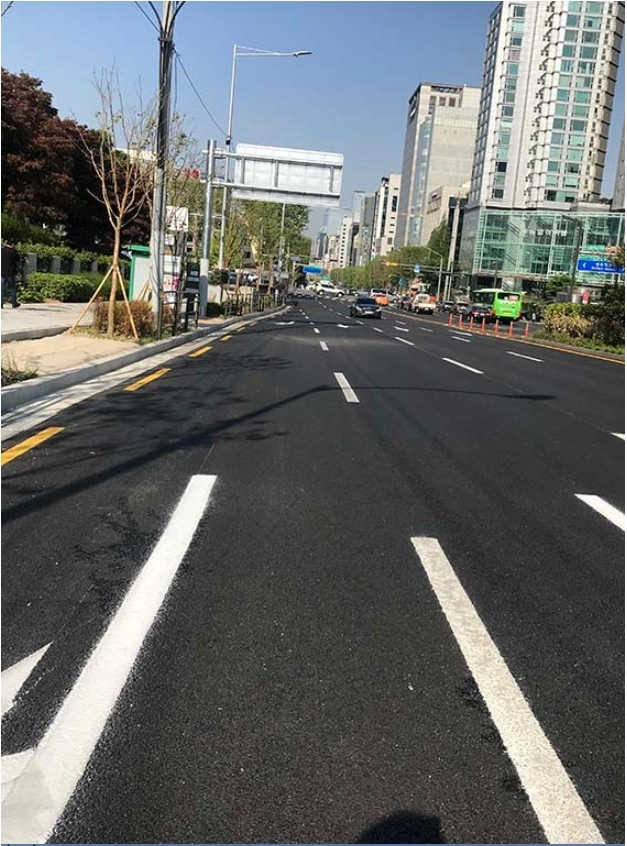

The selection technique for marking glass beads is critical to ensuring their effectiveness in road safety applications, particularly for road markings. These glass beads are added to paints and coatings for reflective properties, improving visibility and safety on roads. The selection of appropriate marking glass beads involves several key factors:

1. Size and Gradation

Size: The diameter of the glass beads affects their reflective performance. Larger beads tend to reflect more light, but smaller beads can provide better adhesion to the road surface. Typically, the size range for road marking beads is between 20 to 150 microns, with beads that are too large or too small impacting the reflective properties and durability.

Gradation: The distribution of bead sizes in the mixture is also crucial. A mixture of bead sizes is often chosen to ensure that there are beads of various diameters for optimal reflective performance and durability. The correct gradation also helps in achieving uniform distribution and a smooth surface.

2. Spherical Shape

Roundness: Glass beads used for road marking must be spherical or nearly spherical. This shape ensures that the beads can reflect light efficiently. A well-rounded bead provides a consistent and high-quality reflective surface that helps in making the road markings visible from a distance, even under low-light conditions.

3. Refractive Index

High Refractive Index: The refractive index of the glass beads determines how effectively they can reflect light. Beads with a high refractive index (typically 1.5 or higher) are preferred as they can better reflect light from vehicle headlights, increasing the visibility of road markings.

4. Surface Quality

Smooth Surface: Glass beads with a smooth, clean surface are more efficient in reflecting light. Any surface roughness can reduce the reflective quality and make the beads more prone to wear. High-quality marking glass beads should be free of cracks, chips, and other imperfections that can compromise their performance.

Coating: Some glass beads are coated with special materials to improve their adhesion to road surfaces or enhance durability. Coatings such as silane or other bonding agents help prevent bead loss and improve the long-term performance of the markings.

5. Durability and Resistance

Wear Resistance: Road marking glass beads must be durable enough to withstand traffic wear and environmental conditions like rain, heat, and UV exposure. They need to maintain their reflective properties over time, even under heavy traffic loads.

Weather Resistance: Glass beads should be resistant to weathering, ensuring that they do not degrade under exposure to UV radiation, moisture, or extreme temperatures.

6. Optical Performance

Reflectivity: The primary purpose of reflective glass beads is to provide high reflectivity to enhance visibility in low-light conditions. Beads with a high reflectivity index are more effective in this role, particularly in nighttime driving situations or during adverse weather conditions like fog or rain.

Brightness: Marking glass beads should have a consistent brightness, providing clear and bright road markings that are visible even from a distance.

7. Standard Compliance

Industry Standards: It’s important to ensure that the glass beads meet the standards set by relevant authorities such as the American Society for Testing and Materials (ASTM) or the European Standard EN 1423. These standards specify the necessary physical and optical properties of the beads, ensuring consistency and reliability in road markings.

8. Cost Considerations

Cost-Effectiveness: While the quality of glass beads is critical, their cost must also be taken into account, especially when considering large-scale projects like road marking. Balancing cost with performance ensures that the chosen glass beads provide value while maintaining the necessary safety and durability standards.

In summary, the selection of marking glass beads involves considering factors such as size, refractive index, shape, surface quality, durability, optical performance, and adherence to standards. Careful selection ensures the road markings are effective, safe, and long-lasting. Anhui TORY have been committed to the development and manufacture of glass beads. Prrofessional and experiences, if you want to know more about glass beads, welcome to consult us anytime.